Overview

RSSV also has exclusive China rights for Texasbased Worx America’s proprietary environmental engineering technologies as well as a 20% pre-IPO equity option. The Worx automated robotic systems quickly clean oil tanks and recover clean oil from waste sludge, resulting in increased sales and cost savings. The Worx multiple line of products and services give RSSV the capacity to offer proprietary solutions for onshore, offshore and subsea oil

production, refining, cleaning and reclamation.

RSSV’s goal is to rapidly gain market share in China’s underserved oil tank cleaning and sludge processing industries through Worx technologies and on-ground training and installation. Senior management of Worx has been working in the field at RSSV’s China operations and has developed a training program for top engineers to go to Houston for further training and on-site systems installation and operations.

The company is led by a solid management team, owns a growing line of proprietary market-specific systems, and has positioned itself well as a high margin, competitive company. With a global focus, RSSV continues to pursue strategic partnerships and the licensing of key technologies for its extensive and growing customer base.

Investment Highlights

– Targeting China’s Oil & Gas Market

– Innovative Oil & Gas Technologies

– Green Energy Efficiency Solutions

Worx America

Worx’s diversified technology platform provides production enhancement solutions to assist energy exploration companies in the development of oil and gas production. Worx’s innovative automated solutions help to increase oil and gas identification and production to meet increasing energy demands worldwide.

The company’s automated robotic systems quickly clean and recover usable oil from oil container waste sludge, resulting in increased sales and decreased tank cleaning time. These technologies reduce tank cleaning time by over 70% and can recover 50% clean oil from waste sludge.

The Worx management team has extensive expertise in developing mechanical designs, spraying technologies, down-hole imaging and motion control automated hydraulic systems. With unmatched level of experience, sophistication and creative design solutions in the field of oil and gas production and recovery, Worx is strategically positioned to capitalize on the booming energy market.

Target Marketing

China’s rapidly expanding mainland oil refining industries are under government mandated environmental pressures. This is forcing oil refineries to modernize, clean up and extract more output or face closure. With China set to become a net oil exporter in 2015, the oil processing and refinery market will have to grow in order to match exportation goals. RSSV is currently focused on leveraging its technologies and partnerships to help meet this demand and secure greater market share.

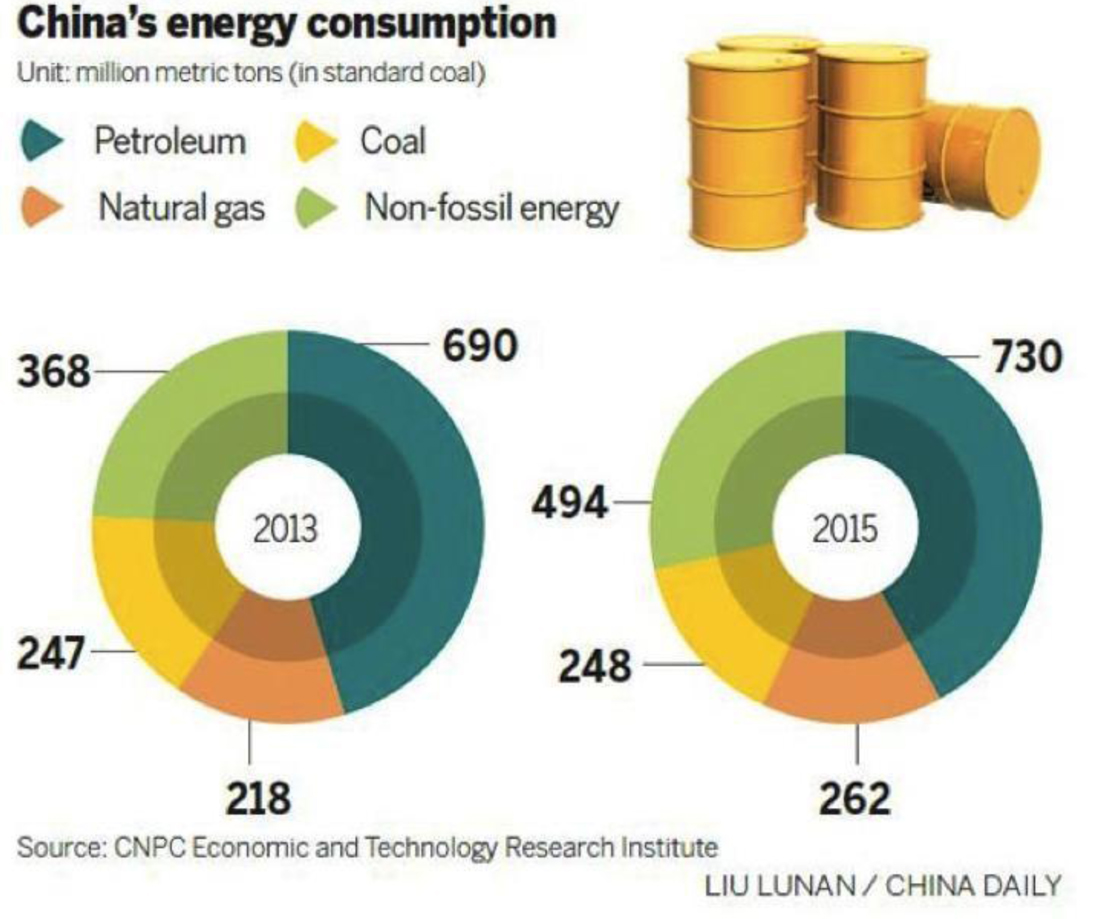

China’s oil consumption will continue to grow in order to keep up with its industrialization initiatives. Supplying oil to a country of more than 3 billion people requires major investments in refinery and processing facilities. With China’s oil demand set to grow 3% year-on-year to 534 million metric tons in 2015, the demand for RSSV technologies will increase as well.

Market Solutions

RSSV’s goal is to rapidly gain market share in China’s under-served oil tank cleaning and sludge processing industries through Worx technologies and on-ground training and installation. With the Worx technologies, RSSV will be able to keep operations going, meet local and national environmental goals and regulations, lower labor costs and lower pay off time for bringing equipment back on line and up to full operating capacity.

Looking Ahead

RSSV’s goal is to rapidly gain market share in China’s under-served oil tank cleaning and sludge processing industries through Worx technologies and on-ground training and installation. With the Worx technologies, RSSV will be able to keep operations going, meet local and national environmental goals and regulations, lower labor costs and lower pay off time for bringing equipment back on line and up to full operating capacity.